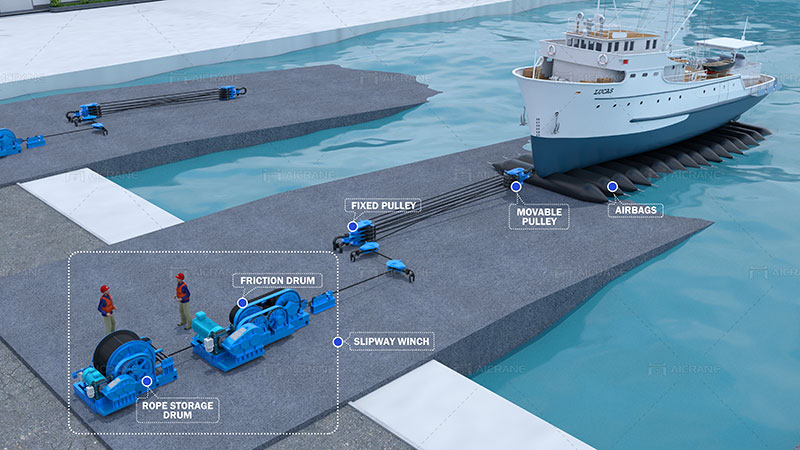

A slipway winch is a vital piece of equipment used in marine and shipyard operations to launch and haul vessels. It plays a critical role in ensuring the safe and efficient movement of boats and ships from land to water and vice versa. The proper operation and installation of slipway winches are essential to maintain the overall functionality and safety of these systems. This article explores the key aspects of slipway winch operation and installation, highlighting important considerations that need to be taken into account.

Slipway Winch Operation

The operation of a slipway winch involves the controlled movement of a vessel along a slipway or inclined ramp leading into the water. This process requires coordination between the winch operator, vessel crew, and possibly other personnel involved in the launch or haul-out operation. The following steps outline the typical slipway winch operation:

1. Preparing the Vessel: Before the operation begins, the vessel must be properly positioned on the slipway. This may involve securing the vessel to the winch’s hauling cable or other attachment points, ensuring stability and safety during movement.

2. Safety Checks: Prior to initiating the movement, the winch operator should conduct thorough safety checks. This includes inspecting the winch components, cables, and connections to ensure they are in good condition. Additionally, the slipway’s surface and alignment should be examined to prevent any obstructions or hazards that could impede the vessel’s movement.

3. Tension and Control: The winch operator will engage the winch machinery to start the movement of the vessel. It’s crucial to maintain proper tension on the hauling cable to ensure a controlled and steady descent or ascent of the vessel. The winch controls should be operated smoothly to avoid abrupt movements that could lead to instability or damage.

4. Monitoring: Throughout the operation, the winch operator should closely monitor the movement of the vessel. This includes observing its alignment with the slipway and adjusting the tension if necessary to maintain a safe and controlled descent or ascent.

5. Communication: Effective communication between the winch operator, vessel crew, and any other personnel involved is essential. Clear communication ensures that everyone is aware of the progress and can respond promptly to any unforeseen situations or adjustments required.

Slipway Winch Installation Considerations

Proper installation of a slipway winch is paramount to its performance, longevity, and the safety of both personnel and vessels. Several key factors should be taken into consideration during the installation process:

1. Site Assessment: Before installing a slipway winch, a thorough assessment of the site is necessary. Factors such as the slipway’s angle, length, and condition, as well as the size and weight of vessels to be moved, must be evaluated to determine the appropriate winch machine capacity and specifications.

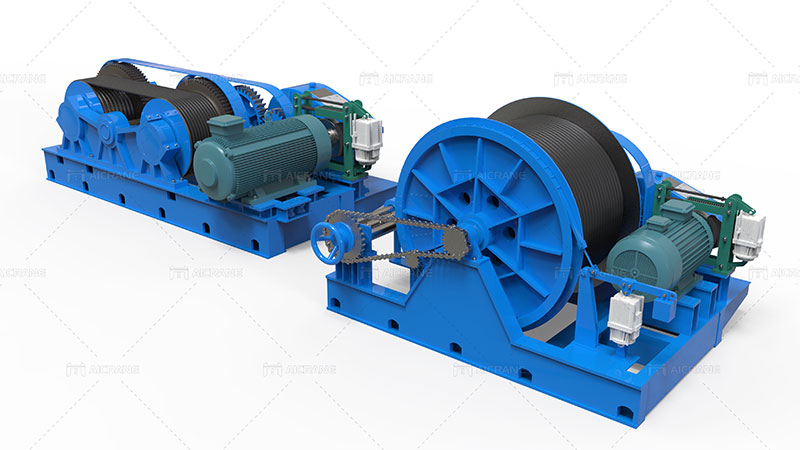

2. Winch Selection: The choice of a suitable winch depends on various factors, including the intended use, vessel size, weight, and the frequency of operations. A winch with the appropriate load capacity and safety features should be selected to ensure smooth and safe operations.

3. Structural Support: The slipway winch must be securely anchored to a stable foundation. The winch’s structural support, such as the mounting platform or frame, should be designed and built to withstand the forces generated during vessel movement.

4. Cable and Hardware: The hauling cable used in slipway winches should be of high quality and appropriate diameter to withstand the load. Proper cable winding and attachment hardware are crucial to prevent cable slippage or failure during operation.

5. Safety Measures: Safety is paramount in slipway winch installation. Adequate fencing, warning signs, and designated areas for personnel during operation should be established to prevent accidents. Emergency stop mechanisms and backup power sources should also be incorporated for immediate response in case of unforeseen events.

6. Environmental Considerations: The installation site’s environmental conditions, such as exposure to saltwater or extreme weather, should be taken into account when selecting boat winch materials and components. Corrosion-resistant materials and protective coatings can extend the winch’s lifespan in such conditions.

7. Maintenance Planning: An effective maintenance plan is essential to ensure the long-term functionality of the slipway winch. Regular inspections, lubrication of moving parts, and timely replacement of worn components are necessary to prevent downtime and ensure safe operations.

Conclusion

Slipway winches are vital tools in marine and shipyard operations, enabling the controlled movement of vessels between land and water. Proper operation and installation considerations are paramount to ensure the safety of personnel, the longevity of the equipment, and the success of the operations. By adhering to safety protocols, conducting thorough site assessments, selecting appropriate equipment, and establishing a robust maintenance plan, slipway winches can continue to play a crucial role in maritime activities for years to come.