In today’s eco-conscious market, the construction industry is under increasing pressure to reduce its environmental footprint. One area experiencing significant transformation is the production of concrete, primarily through the utilization of batching plants. Understanding the differences between environmentally friendly batching plants and their traditional counterparts is crucial for businesses aiming to make informed, sustainable choices.

Introduction to Batching Plants

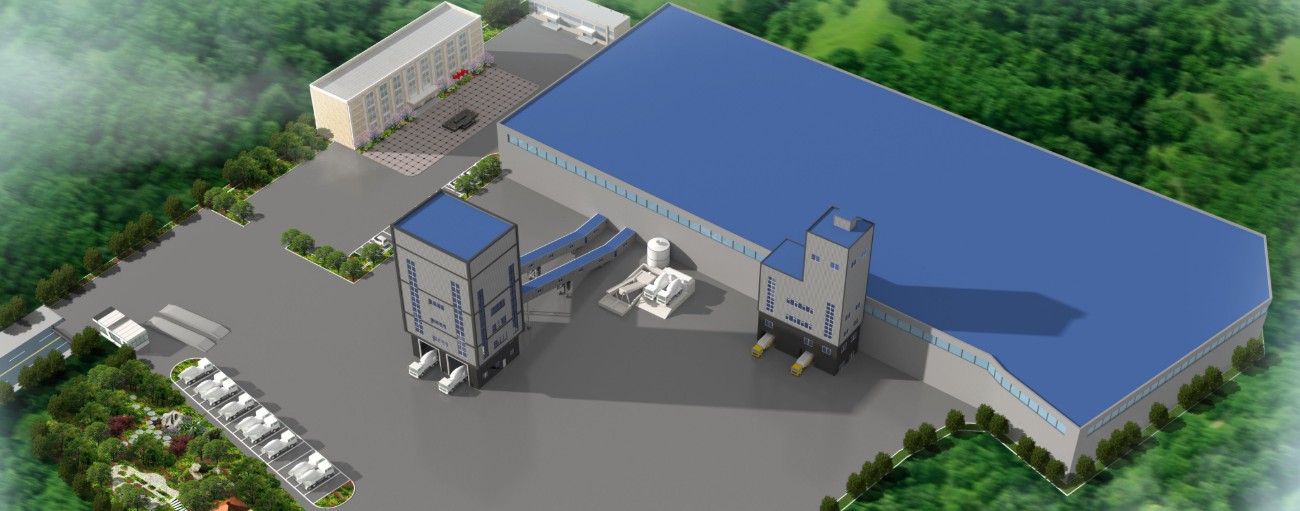

Batching plants are facilities where materials for concrete are combined in specific proportions to produce the mix needed for construction projects. These plants play a pivotal role in ensuring the quality and efficiency of construction efforts worldwide.

The Shift Towards Sustainability

Recently, there’s been a noticeable shift towards environmentally friendly batching plants. This move is not just about adhering to regulations but also about embracing sustainability as a core business value. Let’s delve into how these green batching plants stand apart from traditional setups.

Reducing Carbon Footprint

Environmentally friendly batching plants have a significantly lower carbon footprint. Environmentally friendly batching plant achieves this by using renewable energy sources, like solar or wind power, and incorporating energy-efficient machinery. In contrast, traditional plants often rely on fossil fuels, contributing to higher levels of CO2 emissions.

Water Conservation Techniques

Water usage is another critical factor. Eco-friendly batching plants employ advanced water recycling systems that minimize waste. Traditional plants, however, may lack such features, leading to higher consumption of this precious resource.

Material Efficiency and Waste Reduction

Green batching plants prioritize the efficient use of materials. They utilize supplementary cementitious materials (SCMs) to replace a portion of cement in concrete mixes. SCMs can include industrial by-products like fly ash and slag. This not only reduces the demand for raw materials but also decreases waste. Other concrete batching plants might not adopt these practices, resulting in less material efficiency and more waste.

Noise and Dust Control Measures

Environmental batching plants take measures to control noise and dust emissions, creating a healthier environment for workers and nearby communities. They invest in technologies and structures designed to contain and reduce these pollutants. On the other hand, traditional plants may fall short in implementing adequate control measures.

Economic Benefits Tailored for Customers

Beyond the environmental advantages, opting for an environmentally friendly batching plant offers potential economic benefits. Reduced operational costs, due to savings in energy and materials, can translate to more competitive pricing for customers. Additionally, by aligning with green practices, businesses can enhance their brand image and appeal to a growing segment of eco-aware clients.

Making the Sustainable Choice

In conclusion, the transition from traditional to environmentally friendly batching plants represents a win-win scenario for the construction industry and the planet. It not only addresses urgent environmental concerns but also introduces efficiencies that can benefit the bottom line. For potential customers, understanding these differences is key to choose the batching plant manufacturer. As the industry continues to evolve, those who embrace these greener alternatives will undoubtedly lead the way in sustainable construction.

Remember, every step we take towards sustainability is a stride towards a better future. By choosing environmentally friendly batching plants, you’re not just investing in a piece of equipment; you’re investing in a cleaner, greener tomorrow. Click here to learn more about batching plant. Let’s build a sustainable world together, one batch at a time.